Need assistance on an Automator machine? Request assistance

Why the need for Industrial Marking?

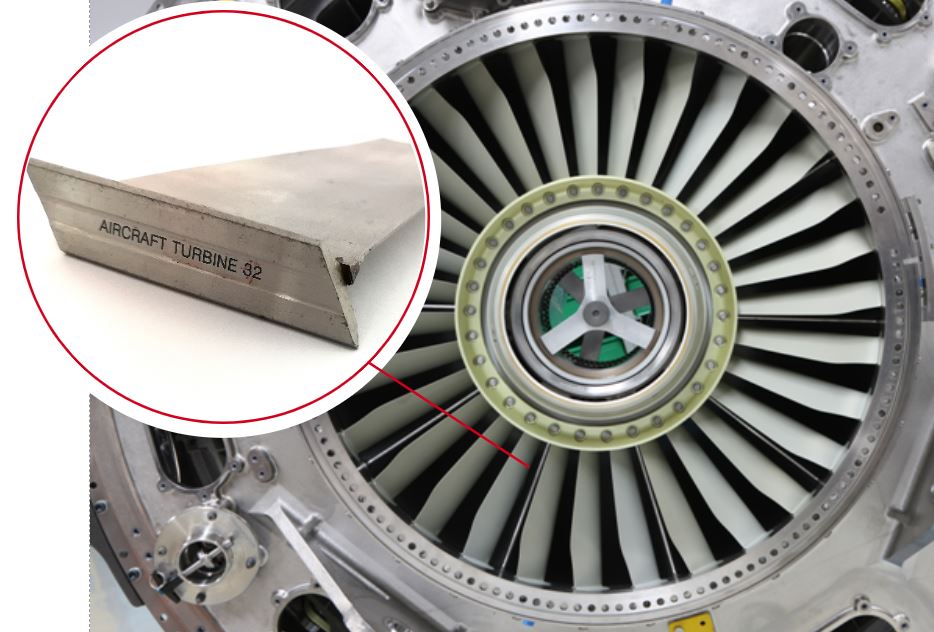

For all industrial sectors, especially the ones of Avionics and Aerospace, there is the need to guarantee quality, traceability and control. All components have to be marked to allow the unitary and permanent identification of every single component. This mechanism allows a particular piece of material to be tracked at any time, from its’ manufacturing date to the final destination of use. This is fundamental for warranty and quality documentation means. Needless to say, industrial marking for aerospace and avionics needs to be precise but at the same time it must be performed delicately to avoid structural impacts on the item. As happens in other industrial sectors, as the medical one, all surfaces have to be marked without damaging or altering the characteristics of the material and/or its resistance.

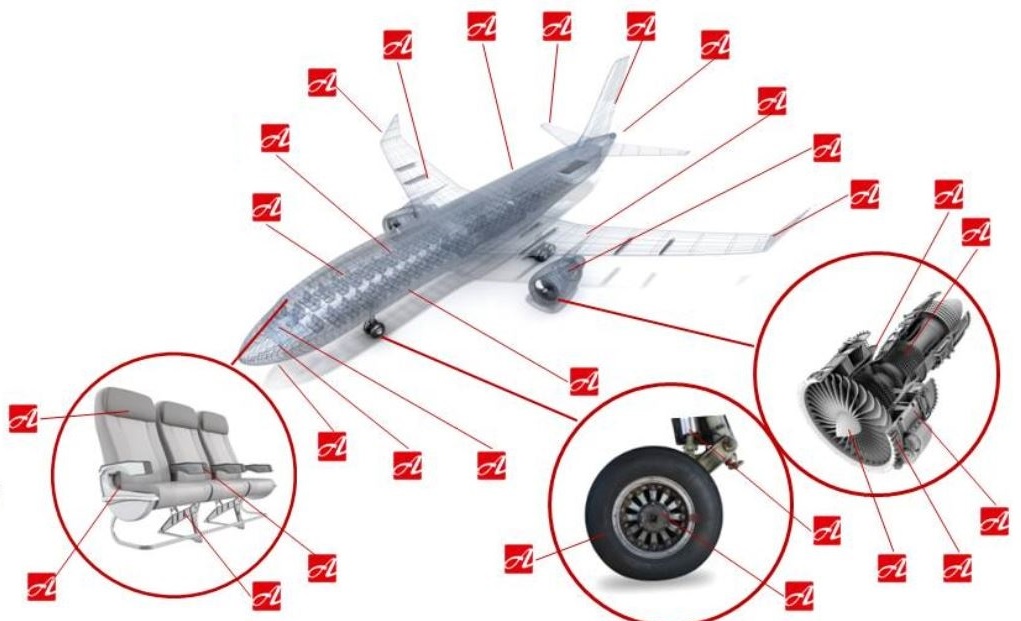

Each little component of any plane must be marked and tracked to follow the requirements of many international industry marking standards, including:

Marking is vital to know everything about a component, who made it, where, when, how, which lifetime has, all info regarding it’s work. In case of problems the inspectors must be able to grab all info and solve the possible problem related to that part. It is for our safety when we travel by plane.

How can we mark Avionic components?

Lasers, dot peen markers, impact machines, roll markers, scribers, hot foil systems and electrolytic or chemical etching are the most used technologies for permanent marking to identify and trace the thousands of aircraft components that are manufactured each year. Also, these marking systems are needed to code and register information such as the serial number, the part number, the batch number, the manufacturing date, the revisions and the repair operations for each single part.

Automator designs, manufactures and sells industrial marking equipment worldwide. We have been doing this since 1940. We are the only international company that provide all marking technologies for all industrial processes.

Special applications for Aerospace and Avionics have been developed specifically for giving manufacturers the ultimate technology for marking, identifying, tracking and, of course, guaranteeing components of the Avionic and Aerospace industrial branch. We have helped clients to meet all international regulations and requirements.

Automator helps to provide solutions for:

Automator provides a wide range of products for marking Avionic and Aerospace parts and materials:

Our company network

A customer can rely on Automator International’s 14 worldwide branches and an extensive network of certified distributors that can provide high quality sales and after-sales support. In Automator’s 80-year history, we are proud to have installed more than 120,000 machines working every day at more than 15,000 customer locations.