All products and parts have to be marked, as we know. But some parts need to be painted after being marked for being protected. This is a very common and huge issue a lot of producers are facing. The paint thickness depends a lot on the product itself, from just some microns up to huge paint coating as for example some valves in oil&gas Industry. So, how can I read the markings I have previously made?

The used marking technology is the first thing to analyze:

1) Impact marking: the impact machine must be very powerful and the impact dies, clichés or types must have a 90 degrees cutting profile. Also they must stay very, very sharp and be changed when loosing the cutting profile.

2) Rollmarking technology: we strongly suggest to use an electric pneumatic roll marking machines (see our “EP Electric Pneumatic” machines) for deep and clear markings. For types and other see what already written in point number 1

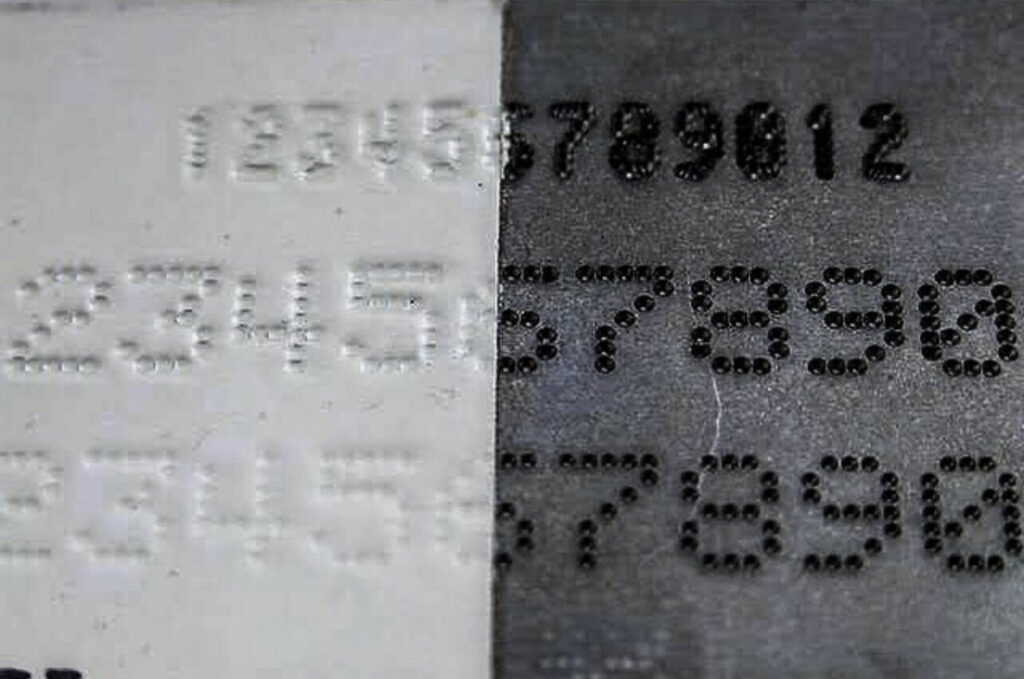

3) Dot peen marking technology: these machines need to be used with special angle impact pins in order to produced a micro cavity on the material.

By doing so the paint will get inside the formed cavity, but, when dry, the marking will still be perfectly readable. See picture below

4) Scribe marking: it’s also possible to use the scribers for marking but we suggest to use the strongest one, called ASM40150, from Automator. This is the only one that eventually will guarantee you the complete success.

5) Laser marking: personally we do not suggest to use laser marking technology to mark on paint. That’s for the following reasons:

– if laser is marking the paint, there will be some chemical reaction fumes that are not safe at all for the operators health and have to be mandatory “token” away

– laser marking will remove the paint and will “agress” the material. By doing so it will take away all paint and protection, so it could be a rust start point

– normally we suggest that laser should only act on the paint and try to modify it without passing through

Why to chose Automator

Automator Marking Systems was funded in 1940 and is focusing 100% on Industrial Marking technologies: we can provide all kinds of Industrial Marking solutions: not only lasers, dot peen or roll machines, but also scribe markers, hot foil and impact machines, presses and chem etch kits. We have always the best solution for your marking need.